(The following is adapted from my article on ROV history for Invention & Technology Magazine).

= = = =

The emergency response to the April 2010 blowout over the Macondo well was a boom time for publicity about deepwater technology. At first, the camera feeds perplexed millions. Why hadn't they heard

about any of this stuff, pre-explosion? The short answer is that ROVs spend most of their time working for the deepwater drilling industry, and that's a field that prefers a low profile.

I first spent time with ROVs and their wranglers fourteen years ago, on a deepwater-drilling ship I was visiting for a feature article in Smithsonian.

Until

the Macondo blowout, deepwater ROVs were over the horizon and

out of mind. They resurfaced as supporting actors during James Cameron's Deepsea Challenger record-breaking stunt two years ago, and now ROVs are back in the news for a little while, assuming MH370 wreckage is found (... and I'm predicting it will be, in the general vicinity of 97E / 30S).

“It's like there are whole underwater

cities down there, the installations are so big and complicated,”

said Robert Wernli, a retired ROV builder for the Navy, about subsea

oil developments. “And it's all installed remotely.”

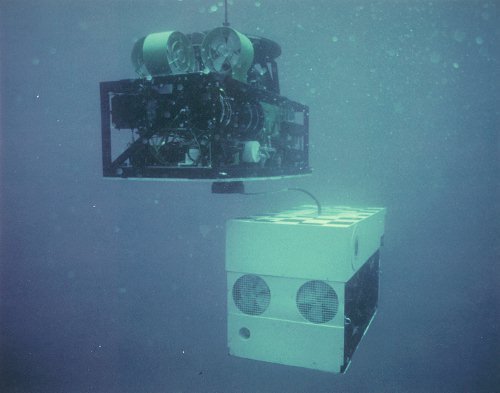

No human eye can look down on the

entire landscape we've been busy building down in the dark, but at

least we know that these boxy underwater robots are the A-Team, in

fact the the only team, when things need fixing in deep, dark places (Offshore Angola photo, BP):

But ROVs have worked such jobs before.

ROVs plucked an H-bomb off a ledge in the Atlantic in 1966, snipped a

Russian submersible loose from a steel antenna, patched up

hurricane-ravaged pipelines, and (on numerous occasions) have helped

lasso giant hunks of drilling equipment out of deep silt following

mishaps above. In deepwater operations around the world, from Brazil

to Asia, nothing can touch ROVs for doing yeoman's work at negligible

risk to humanity: not divers in heated suits breathing exotic gas

mixtures nor people riding around in little submersibles with claws

and cameras.

While divers still offer a unique ability to wiggle into

tight spaces and fix a problem by feel alone, they can't survive

in deepwater fields. Even high-tech “atmospheric

diving suits” -- hard-shelled suits with mandible arms – can't

bring a diver deeper than 2,300 feet and that's at the cost of much

human agility.

Common oilpatch wisdom once regarded

ROVs to be economic only for jobs deeper than a thousand feet; divers

would do the rest. Now, said Drew Michel, ROV consultant and adviser

to the Marine Technology Society, the oil industry is hiring ROVs to

do work in waters as shallow as 150 feet. This was once the exclusive

domain of commercial divers. “We know what they can do now, and how

to use them.”

Because water squelches conventional radio waves, the

“remotely operated” aspect depends on a tether that bundles electrical

and communication lines. While the operator can be floating nearby

inside a tiny manned submersible linked by tether, the operator usually works

from a control room aboard the specialized subsea-intervention vessel

that hosts the ROV, on the surface. A typical ROV has two crews working in the background, each with

three crewmen working 12-hour shifts.

Here's how an oilfield ROV's long night begins:

up top, an ROV has been given the order to go over the side on a

specific mission, say to replace anti-corrosion anodes at a pumping

station in the Mississippi Canyon. Because each trip down and up

wastes valuable time, mechanics make sure that all tools and new

anodes it will need are sent along. Mechanics also ensure

that the buoyancy of the ROV is right for the payload on board the

6,000-foot depth of the worksite.

With the ROV clamped securely inside a

transport cage, safe from being jounced around, the rig rolls down a

vertical track bolted to the ship. Along with its thick umbilical

line, it vanishes under the waves in a cloud of bubbles. Having

reached the end of the track and well below the worst turbulence, the

cage unhitches from its track and begins the long plunge, hanging at

the end of a heavy umbilical cable that provides all services of a

tether, but is reinforced to bear the weight of ROV and cage. The

winch operator stops the cage before it touches down at the bottom;

this avoids stirring up silt each time the ROV returns to fetch

another tool or spare part. To save valuable time, every aspect of

the job has been planned and run on a simulator. Using the high

definition TV cameras, the operator moves in and orders the ROV to

get a grip on the nearest metal structure with one claw, and starts

yanking old anodes with the other.

ROV movements need a high level of

three-dimensional coordination during a complicated response such as wreck recovery or troubleshooting at a wellhead, where a half dozen can be on the job at once. In

addition to all other work, someone must track their

movements ensure that the ROVs don't get their tethers in a knot. (Upon

command, or if contact is lost for an extended period, ROVs can cut

their tethers and slowly rise to the surface to await rescue.)

In the pre-ROV era, any work at depth

was done by divers wearing heavy suits of rubber, canvas and metal.

They clomped along the seafloor in weighted boots, and even heavier

helmets, supplied with air pumped through rubber hoses by tenders.

Typical work, done at harbor depth, was bolting together underwater

pipelines, repairing ships, and salvaging useful goods from sunken

ships that could not be patched and raised.

Advances in SCUBA tanks and regulators,

decompression equipment, and specialized deep-diving mixtures of

hydrogen, helium and oxygen later made it possible to go much deeper.

Divers with the French company COMEX set a world record of 530 meters in one

trial, but at enormous risk. Actual work was barely possible at half that depth,

for brief periods followed by many days of decompression. (Sorry,

Abyss movie fans: no divers ever went down to the sea with liquid-filled

lungs -- there were experiments, but not with divers.)

But, says Drew Michel, such

ultra-deep diving achievements lack practical meaning, given the risks and expense: “No

oil company in their right mind would depend on such a dive,” he told me. Costs

are fantastically high, the work cannot go continuously, and a single

injury shuts down the entire work flow.

At first the limits of deep diving

seemed to point toward the manned submersible, a mini-submarine out

of which a crew would wield tools. In the mid-1960s high-tech

corporations practically swooned over such machines, because (surely) they would open

up the deeps to mineral exploration. And this was a time where nearly everybody worried about strategic minerals.

The mania over manganese

nodules and other bounty touched even companies with no experience

in the subject. American corporations investing in undersea tech

included Westinghouse, Northrop Grumman, North American Rockwell,

Lockheed, General Dynamics, Hughes Tool, and Litton Industries.

“Every major defense contractor went into it,” said Robert

Wernli, ”but after they found the certification requirements were

so expensive to meet, most of the machines built went on blocks for

display.” Even General Mills, maker of cake mixes and cereals, got

into the act by applying for, and winning, a submersible government contract.

“Most of the companies entered

because they saw Howard Hughes getting involved, but he was after a

Russian submarine instead,” said Drew Michel, referring to the

CIA-backed Hughes Glomar Explorer, aka Project Azorian (Photo, US Government):

Among the few craft launched were

Alvin, started by General Mills, but finished by Litton (Photo, General Mills) ...

... and Beaver

Mark IV, built by North American Rockwell, also known as Roughneck (Photo, omegamuseum.com):

The builders equipped Roughneck with manipulators to serve as an

undersea workboat that could install subsea oil and gas equipment in

half-mile deep waters. Assuming that oilfield equipment would always

need the human touch, most concepts for deepwater oilfields circa

1973, such as Exxon's, expected that fleets of diving bells and

submersibles would shuttle workers from the surface down to steel

capsules encapsulating wellheads and pumps. Workers would climb from

submersible to capsule, carry out their jobs in “shirtsleeve” if

claustrophobic conditions, and return to the surface.

ROVs would have

played a minor part in such a human-centered plan (which is portrayed in Abyss, by the way).

While some experiments along this line

were carried out, an entire infrastructure based on thousands of

“subsea work enclosure” capsules scattered across the seafloor

was neither safe nor practical. Until this was discovered (see Part 2), the unmanned subs now known as ROVs

were merely a curiosity, and of interest only to the military, treasure

hunters, and scientists.