= = = = =

Setting

aside military trials (such as the US Navy, which lowered an undersea

TV camera to check on A-bomb blast damage to shipwrecks near Bikini

Atoll, and the British Navy, which used another to look for a sunken

submarine), credit for the first civilian ROV probably goes to

Dimitri Rebikoff of France. Frustrated by the fact that some

Mediterranean wrecks were too deep for divers to investigate, he

installed a camera in a pressure-resistant housing, added a

water-corrected lens, and mounted it on a tether-controlled vehicle

that he dubbed Poodle.

For extra treasure-finding skills, he

added a magnetometer and sonar set. (ROV experts credit Poodle

as the world's ROV, albeit an unarmed one. Having recently built a

diver-driven, one-man underwater scooter called Pegasus for

use by the Submarine Alpine Club of Cannes, France, Rebikoff had a

head start in building Poodle's controls and power train.) On

its first use in 1954, Poodle sent up video of two previously

unexplored Phoenician wrecks, one 700 feet down.

U.S.

Navy labs and Navy contractors built other camera-carrying ROVs, one

of which was Snoopy, notable for its reliance on direct

hydraulic drive, transferred from tender to vehicle through a long

tether-hose (today's ROVs all rely on electrical power, as did the

successor, Electric Snoopy).

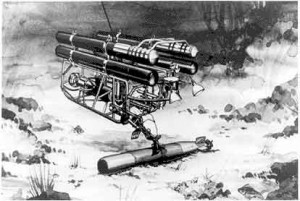

The

first ROV to hit the water with manipulator arms emerged from a US

Navy laboratory in Pasadena, California: Cable-Controlled

Underwater Recovery Vehicle, or CURV.

Originally tasked with

bringing back torpedoes that failed to rise to the surface after test

shots, CURV-I made international news in 1966 off Palomares,

Spain, where an H-bomb had plummeted into the Mediterranean Sea after

a bomber collision. The bomb was resting precariously on the lip of a

steep slope in a skein of parachute shrouds, which for a few

terrifying moments had tangled with the manned submersible Alvin

when that craft had tried to attach lifting shackles. Though at 2,850

feet the bomb lay well below CURV's rated depth, CURV reached the spot without imploding and finished the rigging job. Seven years

later, successor CURV III helped rescue the two-man crew of a

submersible stuck on the sea floor off the Irish coast.

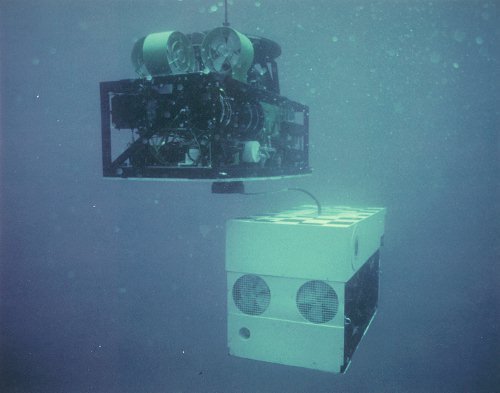

The

Navy's Remote Unmanned Work System, fielded after CURV, was directed

at search and recovery work.

Challenges overcome in its development

pointed the way to today's work-class ROVs. “The Idea was to go to

20,000 feet with all the tools you needed to recover a black box,”

said Wernli. This would give access to the great majority of objects

on the ocean floor, since abyssal trenches are rare. The great depth

could have posed a serious problem in cable handling: If connected

directly to a boat on the surface via a single, thick cable more than

four miles long, the ROV would have been at the mercy of any deep

currents pulling at the line.

The solution was to use two cables: a

strong umbilical line reinforced with Kevlar fiber that plummets

straight down from the tender to a base station (called the Primary

Cable Termination), hanging above the sea floor; and a lightweight

and neutrally buoyant tether that's paid out horizontally as the ROV

ventures off to work nearby.

This arrangement has been very successful, because it keeps cables from

dragging along the sea floors, where the slightest turbulence will stir

up a cloud of talcum-fine silt that blocks visibility for hours.

Work

class ROVs use the same arrangement today, and it's what I saw when shadowing an Oceaneering crew on a drillship in the Gulf of Mexico. Today, the umbilical

terminates at a strong metal cage that serves as a garage for the ROV

when not in use.

The

North Sea turned the tide in favor of ROVs. With exploratory wells having

proven large reserves of oil and gas by 1970, and with oil prices

high after the first oil embargo, production began in 1975. The

conditions – undersea wellheads far from shore, and frequent storms

– were so novel that by 1980, development and installation costs

outran American expenses for the Apollo moonshots. Reserves estimated

at 70 billion barrels kept them going.

The

early years saw dozens of manned submersibles and hundreds of divers

at work, with ROVs at the margin, little more than a curiosity, of

doubtful reliability. Typical was the “flying eyeball” model,

which kept its camera trained on a diver to monitor his safety. But

by 1980, as abilities expanded and reliability improved, ROV fleets

surged.

Although

the North Sea fields are shallower than waters off West Africa,

Brazil, and the Gulf of Mexico, it was a proving ground for critical

advances: connectors that didn't short out in seawater, acoustic

beacons for precise navigation around a sunken structure, robust

manipulators, and high-quality video. Some of the most important

developments at this time had less to do with ROV hardware and more

to do with wellhead hardware.

“That

was the big turning point,” said Wernli. “When [oilfield

engineers] accepted they had to go deep, they started designing the

equipment for that: how the subsea equipment would be operated, how

valves would be turned. The key is that whenever would be needing an

ROV there had to be standard docking so it could plug something in or

manipulate something. In other words, they got the tooling in place.”

As an example, if a valve needs turning, it's better to provide

handles designed specifically for powerful, rotating claws than to

expect the ROV to wield a crescent wrench.

On the

Deepwater Horizon emergency-response spillcam sites, viewers could see ROV

claws wielding shears, circular saws, and diamond wire cutters. ROVs

can also carry drills, abrasive wheels, and jets to cut steel with

high pressure water and abrasive powder. Such tools will be handy

for deepwater decommissioning work, that costly day at the end of a

well's useful life when oil companies are obligated by federal

regulations to cut away old pipes, valves, and other sea-bottom

steelwork for hoisting to the surface. The idea is that nothing will

be left above the mudline, except those structures approved to serve as

artificial reefs.

Decades

from now such work might be turned over to AUVs, or autonomous

underwater vehicles. AUVs are now restricted to going off on

relatively simple missions, and must find their way back or surface

to open up a temporary link via satellite. An AUV's job might include

seawater sampling, surveys of the ocean floor preparatory to

pipelaying, or minehunting for the Navy.

If given the ability to

recharge along the way, AUVs can work for many weeks before

returning. Oil companies have great expectations that, with time, AUVs

can be promoted from surveys to detailed inspection of underwater equipment

such as checking valves for proper function, and then move on to

routine maintenance jobs. This will allow the more elaborate

ROVs to focus on the complicated jobs, such as “workovers” of

aging wells, and replacement of corroded parts and leaking packers.

While

deepwater technology is often compared to space shots, the most

intriguing development, to me, is how experience from the oilfields

suggests that humans can't compete with robots when doing

high-stakes work in dangerous conditions, when figured on a business

basis. Yes, today's underwater "robots" are really remote-control actuators, depending on humans to control the details

of each job at a safe distance, via levers and knobs.

But artificial

intelligence is advancing on a fast track, and with each passing year

robots will be given more authority to exercise judgment, based on how they interpret instrument readings and video

images.

From what I hear, some of the most advanced autonomous underwater vehicles (AUVs) today are devoted to minehunting. Their job is to seek out sleeper mines on the seafloor, an anti-ship tactic quite likely to be used in the next major conflict.

No comments:

Post a Comment